Best-Selling Loading Shovel - GTBZ14JD Electrical Crank Arm Aerial Operation Platform – Chengong

Best-Selling Loading Shovel - GTBZ14JD Electrical Crank Arm Aerial Operation Platform – Chengong Detail:

I. Product overviews and features

Electric crank aerial work platforms are developed by XCMG, compact structures and vehicle body 1.75m wide. Intelligent and perfect control system features the humanized layout, the maintenance-free design and easy use and maintenance, providing the multiple options and comprehensive safety.

[Advantages and features]

●Σ-shaped boom combine and zero – drift design make it more productive.

●As small as 3.15m turning radius enables the machine to work in narrow space.

●48V and 420Ah large-capacity battery makes the cruising ability longer.

●Advanced AC motor running technologies; steering differential control technologies; powerful and steady actions; gradeability up to 30%

●DC pump and proportional control technologies are energy-saving and effective, making the work steadier and safer.

●Environment friendly, zero emission, low noise, traceless traveling, suitable for indoor construction.

II. Introduction of Main Parts

1. Chassis part

Main configurations; 2WD, two wheel steering, solid tires.

(1) Maximum driving speed at 5.2km/h.

(2) Maximum gradeability at 30%.

(3) The built-in traveling reducer that integrates the motor and reducer is applied and two driving speeds (high speed and low speed) are provided to meet the driving demands of the machine under different environments. The traveling mechanism features self-braking function while traveling on slopes and is equipped with clutch device to ease the towing in event of malfunction.

(4) Crank-slider mechanism for turning to realize smaller turning radius;

2. Boom part

(1) Foldable arm + telescopic arm + crank

(2) Boom material – The boom is welded from high strength steel to realize lightweight and high safety.

(3) Foldable arm is of two sets of parallelogram structures, with linkage in between, and could move at the same time with the aid of luffing cylinder, making the work more effective.

(4) Two sections of telescopic arms being of single cylinder telescopic type; crank arms being of parallelogram

3. Turntable part

(1) 355° discontinuous turning and two mounting holes for transferring lock pins;

(2) The turntable is composed of single plate with reinforcing rib; the hinge points are highly laid and counterweight is placed at the rear of turntable;

4. Platform part

(1) 1.4m×0.7m large work platform.

(2) 160° rotatable platform.

(3) Up to 227kg carrying capacity.

(4) Electro-hydraulic proportional automatic leveling system.

5. Hydraulic system

(1) Hydraulic parts – The main parts, including hydraulic pump and master valve, adopt international renowned brand products.

(2) Hydraulic system is driven with battery pump; gear pump is directly driven with motor.

(3) Superstructure hydraulic system is of constant-flow gear pump system: based on the electric-hydraulic proportional control technologies, the machine could perform the slewing of superstructure, the luffing of boom, the retracting/extending of boom, the swinging of work platform; the main valve of superstructure is of electric-hydraulic proportional valve.

(4) Installed emergency power unit – It can ensure that the boom can be retracted to the driving status in event of malfunction of engine or oil pump.

6. Electric system

(1) PLC control technology – One controller is provided each for the turntable and platform. A control boxy is installed for the chassis turntable and platform respectively to control the chassis, turntable, boom, and platform.

(2) Main control items – chassis steering and traveling control; the slewing of turntable; boom telescopic; luffing control; the slewing of platform

(3) Multiple safety protection methods – monitoring of motor drive; protection of motor overloading; vehicle-tilting warning; overloading warning; high-speed running limited; emergency drop;

III. Configuration of GTBZ14JD Main Parts

| S/N | Name | Quantity | Note |

| Battery | 8 | Trojan | |

| Charger | 1 | Dongguan Longsheng | |

| Motor drive | 2 | CURTIS | |

| Traveling reducer | 2 | Omni | |

| Running AC motor | 2 | KDS | |

| Main battery pump | 1 | BUCHER | |

| Auxiliary battery pump | 1 | BUCHER | |

| Main pump | 1 | Sant | |

| Swing cylinder | 1 | USA HELAC | |

| Leveling cylinder | 2 | Chengdu Chenggang Hydraulic Equipment Co., Ltd./XCMG Hydraulic Parts Co., Ltd. | |

| Luffing cylinder of No. 1 arm | 2 | ||

| Luffing cylinder of No. 2 arm | 1 | ||

| Crank arm cylinder | 1 | ||

| Telescopic cylinder | 1 | ||

| Steering cylinder | 1 | ||

| Balance valve | 5 | Sant/EATON | |

| Controller | 2 | Hirschmann | |

| Double-shaft inclination sensor | 1 | Parker | |

| Display | 1 | Xuzhou Hirschmann Electronic Co., Ltd. | |

| Joystick | 2 | Danfoss | |

| Foot switch | 1 | SUNS | |

| Slewing and drive | 1 | Huafang | |

| Swing motor | 1 | White | |

| Tires | 4 | Laizhou Yishimai |

IV. Table of GTBZ14JD Main Technical Parameters

| Item | Parameter |

| Parameters of running state | |

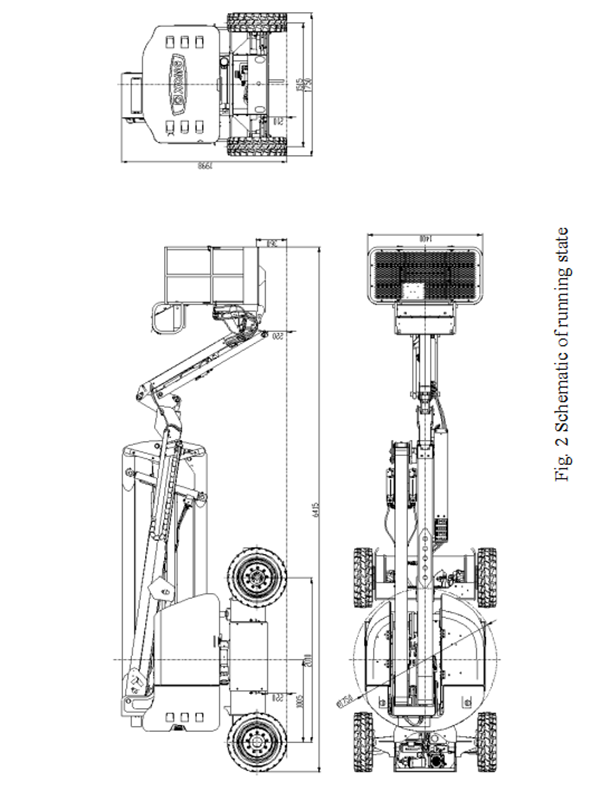

| Overall dimensions (L × W × H) | 6.42×1.75×2 m |

| Working platform overall dimensions | 1.4×0.7×1.15 m |

| Maximum speed | 5.2 km/h |

| Maximum gradeability | ≥30 % |

| Min. external turning radius | ≤3.15 m |

| Ground clearance/m (centre) | 0.21 m |

| Wheelbase | 2 m |

| Total mass | 6500 kg |

| Main Operation Performance Parameters | |

| Rated working height | 15.5 m |

| Maximum platform height | 13.8 m |

| Max. work range | 8 m |

| Maximum net spanning height | 7.03 m |

| Scope of luffing of No. 1 arm | 0°~60° |

| Scope of luffing of No. 2 arm | -8°~75° |

| Scope of crank arm luffing | -60°~80° |

| Scope of platform swing | 180° |

| Slewing angle | 355° |

| Slewing radius of turntable | 0.875 m |

| Maximum loading | 227 kg |

| Maximum rearward slewing | 0 m |

| Control system | 12V DC proportional control |

| Tire | 250-15 solid tire, optional 240/55 D17.5 |

| Power parameters | |

| Power source | 420 Ah/48 V DC |

| Power unit | 4 kw/48 V DC |

| Auxiliary power unit | 2.2 kw/24 V DC |

| Running motor | 3.3 kw/32 V AC |

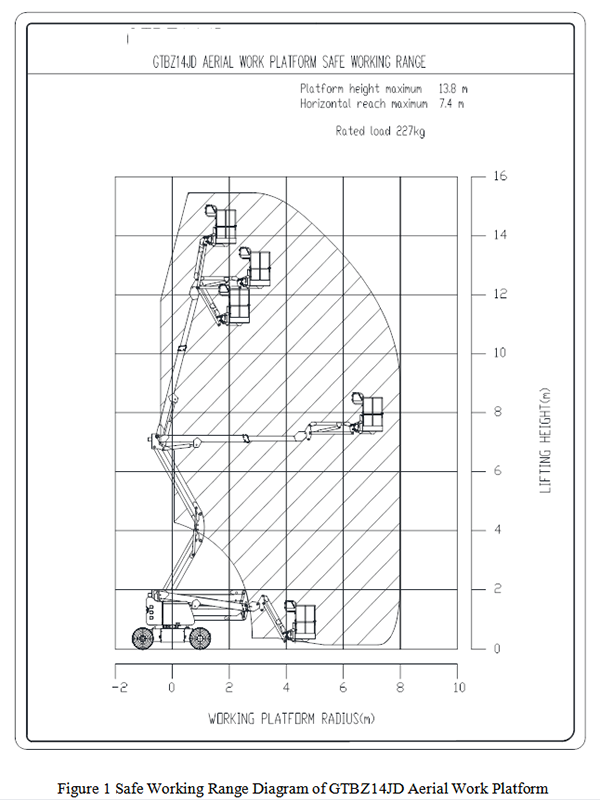

V. Safe Working Range Diagram of Machine

Attachment: optional configurations

6.1 Environment-friendly solid tire (traceless)

6.2 Power supply of platform

The hydraulic generator or the external power supply is wired to this platform for use.

Power wire specification:4×4mm2

Rated current : 35A

6.3 Air pipe of platform

The external air supply is piped to this platform for use.

Air pipe diameter: 8mm

6.4 Anti-impact bracket of platform

The foldable anti-impact device should protect the operator from being impacted with the above item during the platform rising, and could also be foldable, not occupying the work space.

Product detail pictures:

Related Product Guide:

Each individual member from our large performance revenue crew values customers' needs and company communication for Best-Selling Loading Shovel - GTBZ14JD Electrical Crank Arm Aerial Operation Platform – Chengong , The product will supply to all over the world, such as: Berlin, Bangladesh, Bangladesh, We follow superior mechanism to process these goods that ensure optimum durability and reliability of the goods. We follow latest effective washing and straightening processes that enable us to supply unmatched quality of items for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!