GTJZ0607 Scissor Aerial Operation Platform

I. Product overviews and features

The new aerial work truck developed by XCMG has a working height of 7.8m, a width of 0.76m, a rated load of 230kg, a maximum platform length of 2.6m and a maximum slope of 25%. With compact structure, advanced performance and complete safety devices, the truck is especially suitable for construction. In addition. It is free from any pollution, smooth lifting and lowering, easy to control and maintain. Therefore, this platform is widely used in warehouses, factories, airports and railway stations, especially in narrow workplaces.

[Advantages and features]

●Effective and energy-saving electric-drive system features zero emission and low noise, together with the traceless tires, enabling this machine easily to work in enclosed environments such as office building, hospitals and schools and minimizing the effect on environment.

●Active protective mechanism such as pothole protective mechanism and the self-developed safety control system feature the humanized design and the rich options, meeting the customer needing for safety, reliability and intelligence.

●Narrow- structure design enables the complete vehicle to easily pass through a single gateway; foldable fence could make the transportation easier

●“Zero Turning Radius ”is unique and enable machine to corner in narrow room.

●Max. payload at 230kg, leading the industry.

●Maximum traveling speed 4km/h and 25% gradeability make the driving easier.

II. Introduction of Main Parts

1. Chassis

Main configurations: two wheel steering, 4×2 drive, auto brake system, auto pothole protective system, traceless solid rubber tires, and manual release of brake

(1) Maximum driving speed at 4km/h.

(2) Maximum gradeability at 25%.

(3) The tail of chassis is equipped with standard hole for the transportation of fork.

(3) Auto pit protection system—ensure safety for platform lifting

(4) Traceless solid rubber tires - high payload, steady running and environment friendly

(5) 4×2 driving; the turn wheels are also driving wheels; three driving speed gears; all-travel walking is allowed;

(6) Auto brake system-- the machine brakes when it stops traveling or stops on a slope; besides, an additional hand brake for emergency;

2. Boom

(1) Single luffing cylinder + four sets of scissor type boom

(2) High-strength steel — boom light-weighted and safer;

(3) Matched strength and rigid - make sure the boom is reliable.

(4) Inspecting frame —keeps the inspection safe

3. Work platform

(1) Main platform could have the payload up to 230kg and the sub-platform to 115kg.

(2) Work platform length × width: 1.88 m × 0.76m;

(3) Sub-platform can be extended 0.9m in one direction

(4) Platform door can be self-locking

(5) Platform guardrail can be folded

4. Hydraulic system

(1) Hydraulic components - hydraulic pump, main valve, hydraulic motor and brake are all made by domestic (or international) famous manufacturers.

(2) The hydraulic system is driven by motor-driven gear pump, thus realizing the lifting and lowering of the platform and the running and steering of the platform.

(3) The lifting cylinder is equipped with emergency descending valve - to ensure that the platform can descend to retraction at a stable speed even in case of accident or power failure.

(4) The lifting cylinder is equipped with hydraulic lock to ensure that the working platform can reliably maintain the height after the hydraulic hose breaks.

5. Electrical system

(1) The electrical system adopts CAN bus control technology. The chassis is equipped with a controller and the platform is equipped with a control handle. The communication between the chassis and the platform controller is realized through CAN bus, so as to control the action of the machine.

(2) The proportional control technology makes each action stable.

(3) Electrical system controls all movements, including left/right steering, front/rear travel, high/low speed switching and lifting of the working platform.

(4) Multiple safety and warning methods: tilt protection; handle interlock; automatic pothole protection; automatic low speed protection at high altitude; three-second descent pause; heavy load warning system (optional); charge protection system; emergency button; action buzzer, inverter flashing light, horn, timer and fault diagnosis system.

III. Configuration of Main Elements

| S/N | Key component | Quantity | Brand | Note |

| 1 | Controller | 1 | Hirschmann/North Valley | |

| 2 | Main pump | 1 | Sant/Bucher | |

| 3 | Hydraulic motor | 2 | Danfoss | |

| 4 | Hydraulic brake | 2 | Danfoss | |

| 5 | Power unit | 1 | Bucher/GERI | |

| 6 | Derricking cylinder | 1 | XCMG Hydraulic department / Dacheng / Shengbang / Diaojiang | |

| 7 | Steering cylinder | 1 | ||

| 8 | Battery | 4 | Trojan/Leoch | |

| 9 | Charger | 1 | GPD | |

| 10 | Limit switch | 2 | Honeywell/CNTD | |

| 11 | Testing switch | 2 | Honeywell/CNTD | |

| 12 | Motor drive | 1 | Curtis | |

| 13 | Tire | 4 | Exmile/Topower | |

| 14 | Angle sensor | 1 | Honeywell | Optional |

| 15 | Pressure sensor | 1 | danfoss | Optional |

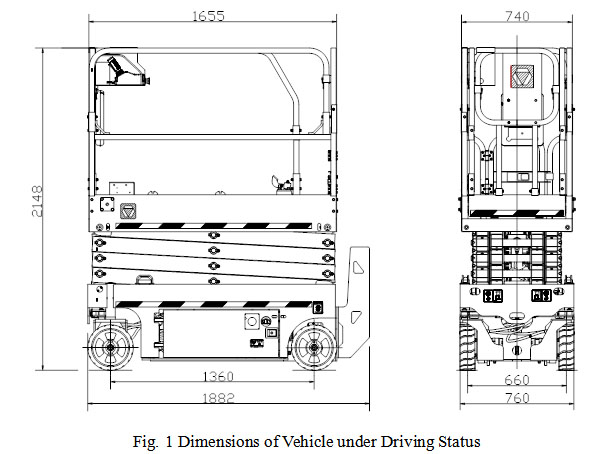

IV. Table of Main Technical Parameters

| Item | Unit | Parameter | Allowable tolerance | ||

| Dimension of machine | Length (without ladder) | mm | 1882(1665) | ±0.5% | |

| Width | mm | 760 | |||

| Height(platform folded) | mm | 2148(1770) | |||

| Wheelbase | mm | 1360 | ±0.5 % | ||

| Wheel track | mm | 660 | ±0.5 % | ||

| Minimum ground clearance (Pit protector ascending/descending) | mm | 60/20 | ±5 % | ||

| Dimension of working platform | Length | mm | 1655 | ±0.5 % | |

| Width | mm | 740 | |||

| Height | mm | 1226 | |||

| Extension length of the auxiliary platform | mm | 900 | |||

| Centroid position of machine | Horizontal distance to front shaft | mm | 750 | ±0.5 % | |

| Height of centroid | mm | 570 | |||

| Total mass of machine | kg | 1520 | ±3% | ||

| Max. height of platform | m | 5.8 | ±1 % | ||

| Min. height of platform | m | 1.01 | ±1 % | ||

| Maximum working height | m | 7.8 | ±1 % | ||

| Minimum turning radius (inner wheel/outer wheel) | m | 0/1.75 | ±1 % | ||

| Rated load of working platform | kg | 230 | — | ||

| Payload after work platform extended | kg | 115 | — | ||

| Lifting time of working platform | s | 15-30 | — | ||

| Lowering time of working platform | s | 22-35 | — | ||

| Max. running speed at low position. | km/h | ≥4 | — | ||

| Max. traveling speed at high altitude | km/h | ≥0.8 | — | ||

| Maximum gradeability | % | 25 | — | ||

| Tilt warning angle (side/forward and backward) | ° | 1.5/3 | |||

| Lifting / running motor | Model | — | — | — | |

| Rated power | kW | 3.3 | — | ||

| Manufacturer | — | — | — | ||

| Battery | Model | — | T105/DT106 | — | |

| Voltage | v | 24 | — | ||

| Capacity | Ah | 225 | — | ||

| Manufacturer | — | Trojan/Leoch | — | ||

| Tire models | — | Traceless and solid /305×100 | — | ||

V. Dimensional Diagram of Vehicle in Running State

Attachment: optional configurations

(1) Load warning system

(2) Work lamp of platform

(3) Connected to the air pipe of work platform

(4) Connected to the AC power supply of work platform