GTJZ1012 Scissor Aerial Operation Platform

I. Product overviews and features

New aerial work platform developed by XCMG has the work height at 12m, the vehicle width at 1.17m, the rated load at 320kg, max. platform length at 3.2m and max. gradeability at 25%. This vehicle features compact structure, advanced performance, completed safety devices, specially suitable for construction. In addition. It is free of any pollution, with steady lifting / lowering, easy control and maintenance. Therefore, this kind of platforms are widely applied to warehouses, factories, airports, and train stations, especially the narrow work sites.

[Advantages and features]

●Effective and energy-saving electric-drive system features zero emission and low noise, together with the traceless tires, enabling this machine easily to work in enclosed environments such as office building, hospitals and schools and minimizing the effect on environment.

●Active protective mechanism such as pothole protective mechanism and the self-developed safety control system feature the humanized design and the rich options, meeting the customer needing for safety, reliability and intelligence.

●Work platform is able to extend out, enlarging the work space, together with the foldable fence making the transportation easier.

●“Zero Turning Radius ”is unique and enable machine to corner in narrow room.

●Max. payload at 320kg, leading the industry.

●Maximum traveling speed 3.2km/h and 25% gradeability make the driving easier.

I. Product overviews and features

XCMG scissors aerial work platform GTJZ1012 have many advatages as below:

1. Convenient Transportation And Stable Operation

The telescoping sub platform achieves large working space and works with folding platform to realize easier transportation and translocation. The industry-leading automatic pit protection system and the widened wheel tread design enable your free operations even on rough ground.

2. Environmental Cons Truction And Convenient Service

Pure electric drive, zero release,low noise and more environmental construction. Overall swing-type tray is convenient for service and maintenance.

3. General And Modular Design

The modular design for the machine guarantees the universality of parts, makes the customers' repairs and maintenances easier, and achieves more competitive cost.

II. Introduction of Main Parts

1. Chassis

Main configuration: two-wheel steering, 4×2 drive, automatic brake system, automatic pothole protection system, non-marking solid rubber tires, manual brake release

(1) The maximum driving speed is 3.2 km/h.

(2) Maximum gradient is 25%.

(3) Standard hole at the rear of the chassis for transporting forks

(3) Automatic pit protection system - ensures the safety of platform lifting.

(4) Trackless solid rubber tires - high payload, stable operation and environment friendly

(5) 4×2 drive, turning wheels are also drive wheels, three drive speeds, allowing full travel.

(6) Automatic brake system - the machine brakes automatically when it stops traveling or stops on a slope; in addition, there is an extra hand brake for emergency.

2. Boom

(1) Double luffing cylinders + five sets of shear boom.

(2) High strength steel - boom is light weight and safer.

(3) Matching strength and stiffness - ensure reliable boom.

(4) Inspection frame - keep the safety of inspection

3. Working platform

(1) Payload up to 320kg for the main platform and 115kg for the secondary platform;

(2) Work platform length × width: 2.27 m × 1.12m;

(3) Sub-platform could prolong in one way by 0.9m;

(4) Platform gate self-locked

(5) Platform guard foldable

4. Hydraulic system

(1) Hydraulic elements - hydraulic pump, main valve, hydraulic motor and brake are from the domestic (or international) famous manufacturers

(2) The hydraulic system is driven with the motor-driven gear pump, so as to raise or lower the platform and to run and steer the platform.

(3) The hoisting cylinder is equipped with an emergency lowering valve - making sure the platform could lower to the retraction at steady speed even at accident or electricity cut off.

(4) The lifting cylinder is equipped with the hydraulic lock to ensure the reliable keeping height of work platform after the hydraulic hose is broken.

5. Electric system

(1) The electrical system uses the CAN bus control technology. The chassis is equipped with controller, the platform is fitted with control handle and the communication between the chassis and the platform controller is realized through CAN bus so as to control the action of machine.

(2) The proportional control technologies make each action steady.

(3) Electrical system controls all the actions, including the leftward/rightward steering, the forward/backward traveling, the changeover between high and low speeds and the lifting/lowering of work platform.

(4) Multiple safety and warning methods: tilting protective; inter-locking of handles; automatic pothole protection; auto low-speed protection at high altitude; falling pause for three seconds; heavy-loaded warning system (optional); charging protective system; emergency button; action buzzer, frequency flasher, horn, timer and fault diagnosis system.

III. Configuration of Main Elements

| S/N | Key component | Quantity | Brand | Note |

| 1 | Controller | 1 | Hirschmann/North Valley | |

| 2 | Main pump | 1 | Sant/Bucher | |

| 3 | Hydraulic motor | 2 | Danfoss | |

| 4 | Hydraulic brake | 2 | Danfoss | |

| 5 | Power unit | 1 | Bucher/GERI | |

| 6 | Derricking cylinder | 1 | XCMG Hydraulic department / Dacheng / Shengbang / Diaojiang | |

| 7 | Steering cylinder | 1 | ||

| 8 | Battery | 4 | Trojan/Leoch | |

| 9 | Charger | 1 | GPD | |

| 10 | Limit switch | 2 | Honeywell/CNTD | |

| 11 | Testing switch | 2 | Honeywell/CNTD | |

| 12 | Motor drive | 1 | Curtis | |

| 13 | Tire | 4 | Exmile/Topower | |

| 14 | Angle sensor | 1 | Honeywell | Optional |

| 15 | Pressure sensor | 1 | danfoss | Optional |

IV. Table of Main Technical Parameters

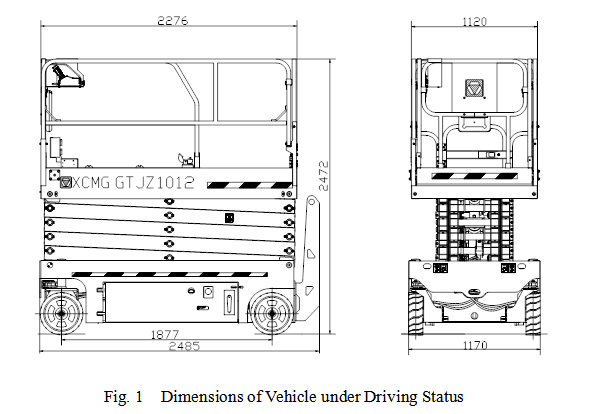

| Item | Unit | Parameter | Allowable tolerance | |

| Dimension of machine | Length (without ladder) | mm | 2485 (2285) | ±0.5 % |

| Width | mm | 1170 | ||

| Height(platform folded) | mm | 2472 (1908) | ||

| Wheelbase | mm | 1876 | ±0.5 % | |

| Wheel track | mm | 1043 | ±0.5 % | |

| Minimum ground clearance (Pit protector ascending/descending) | mm | 100/20 | ±5 % | |

| Dimension of working platform | Length | mm | 2276 | ±0.5 % |

| Width | mm | 1120 | ||

| Height | mm | 1254 | ||

| Extension length of the auxiliary platform | mm | 900 | ||

| Centroid position of machine | Horizontal distance to front shaft | mm | 950 | ±0.5 % |

| Height of centroid | mm | 663 | ||

| Total mass of machine | kg | 2940 | ±3 % | |

| Max. height of platform | m | 10 | ±1 % | |

| Min. height of platform | m | 1.34 | ±1 % | |

| Maximum working height | m | 12 | ±1 % | |

| Minimum turning radius (inner wheel/outer wheel) | m | 0/2.3 | ±1 % | |

| Rated load of working platform | kg | 320 | — | |

| Payload after work platform extended | kg | 115 | — | |

| Lifting time of working platform | s | 50-75 | — | |

| Lowering time of working platform | s | 43-65 | — | |

| Max. running speed at low position. | km/h | ≥3.2 | — | |

| Max. traveling speed at high altitude | km/h | ≥0.8 | — | |

| Maximum gradeability | % | 25 | — | |

| Tilt warning angle (side/forward and backward) | ° | 1.5/3 | ||

| Lifting / running motor | Model | — | — | — |

| Rated power | kW | 3.3 | — | |

| Manufacturer | — | — | — | |

| Battery | Model | — | T125/3-EV-225 | — |

| Voltage | v | 24 | — | |

| Capacity | Ah | 240 | — | |

| Manufacturer | — | Trojan/Leoch | — | |

| Tire models | — | Traceless and solid /381×127 | — | |

V. Dimensional Diagram of Vehicle in Running State

Attachment: optional configurations

(1) Load warning system

(2) Work lamp of platform

(3) Connected to the air pipe of work platform

(4) Connected to the AC power supply of work platform